OTHER SPECIALITY CHEMICALS & SERVICES

We have a wide range of specialty chemical designed for specific application processes.

MEE ANTISCALANTS

Multiple Effect Evaporators (MEE) are used for evaporating high TDS and/or high COD effluents in industrial applications, MEE Plants are installed wherever large volumes of water is required to be evaporated for concentration of salts, these plants are also used for concentrating RO rejects. Scale formation in MEE Plants is a common phenomenon and it hinders the heat transfer process thereby reducing the overall efficiency of the system.

Antiscalants are used to retard scale formation and antifoaming agents are used to retard foaming in MEE Plants, this ensures consistent performance of the MEE Plant and reduces cleaning frequency and condensate quality issues. Bio-Teck range of Antiscalant for MEE & MED Plants and are widely used in Industries for their outstanding benefits,

Features:

| Retards Scale Formation. | |

| Lower dosage rate as compared to other Antiscalants. | |

| Modifies Scale Morphology and generates easy to clean scales. | |

| Increases up-time and reduces down-time by increasing operational hours between two cleaning cycles. | |

| Gives better throughput by maintaining clean surface. | |

| Suitable for High temperature operations. |

DEFOAMERS

We provide a complete range of defoamers for different industries such as Adhesive, Agriculture, and Bitumen, Construction, Dyes & Pigments, Emulsion polymerization, Oilfield & petroleum, Paper & Pulp Sugar, Soaps & Detergents, Waste water Treatment.

Our Silicon based defoamer is found to be powerful and highly effective due to its unique properties & can be used in practically all industrial applications where unwanted foam creates problems in manufacturing.

Features:

Wide Range of Applications Use.Low Surface Tension.

Good Thermal Stability.

Good Chemical Stability.

Physiological Inertia.

Strong Defoaming Power.

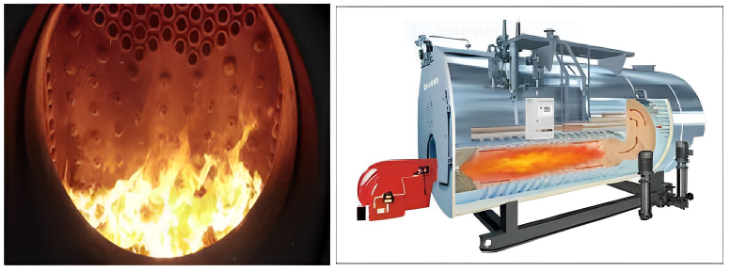

FIRESIDE FUEL ADDITIVES

The primary aim of combustion is to obtain maximum amount of steam from each unit of fuel. But impurities in fuels and operational problems are limitations to achieve maximum output from burned fuel. The impurities in fuel can lead to formation of slag in boiler furnace, clinkers on the fuel bed and the presence of sulphur can lead to the cold end corrosion.

A fireside fuel additive plays an important role in complete combustion of fuel along with a control on corrosion deposits, slagging clinker formation, reduction in air borne pollution emission as well as inhibition of fouling.

Multipurpose Solid & Liquid Fuel Additive

Our Multipurpose Solid Fuel Additive is a free-flowing powder designed primarily for treating coal, wood, and other solid fuels. It acts as combustion catalyst resulting in improved combustion efficiency. It has an anti–fouling agent that helps to keep heat transfer surfaces clean thus improving the steam generation. It softens the hard clinker, while preventing hard clinker formation.

Therefore helps in reducing the boiler maintenance, provide ease in cleaning and increases the boiler availability for long term operation. It promotes smoke free combustion, resulting in improved fuel economy. Our chemical compound is a perfect blend of combustion aid chemicals in the form of liquid/powder canister for fireside cleaning of furnace. It also comprises of combustion catalyst, oxidizing chemicals, dispersants, and corrosion inhibitors.

Therefore, the cleaning of furnace wall improves the heat transfer and boiler efficiency with minimum breakdown.

Features:

| Complete Combustion of Fuel&Reduces Fuel Consumption. | |

| Reduced Slag & Clinker Formation. | |

| Minimizes Corrosion & Cold Corrosion. | |

| Reduces Acid Smut Formation. | |

| Decrease in Unburned Carbon in Ash. | |

| Increase in Furnace Efficiency&Decreases Particulate Matter from Stack. |

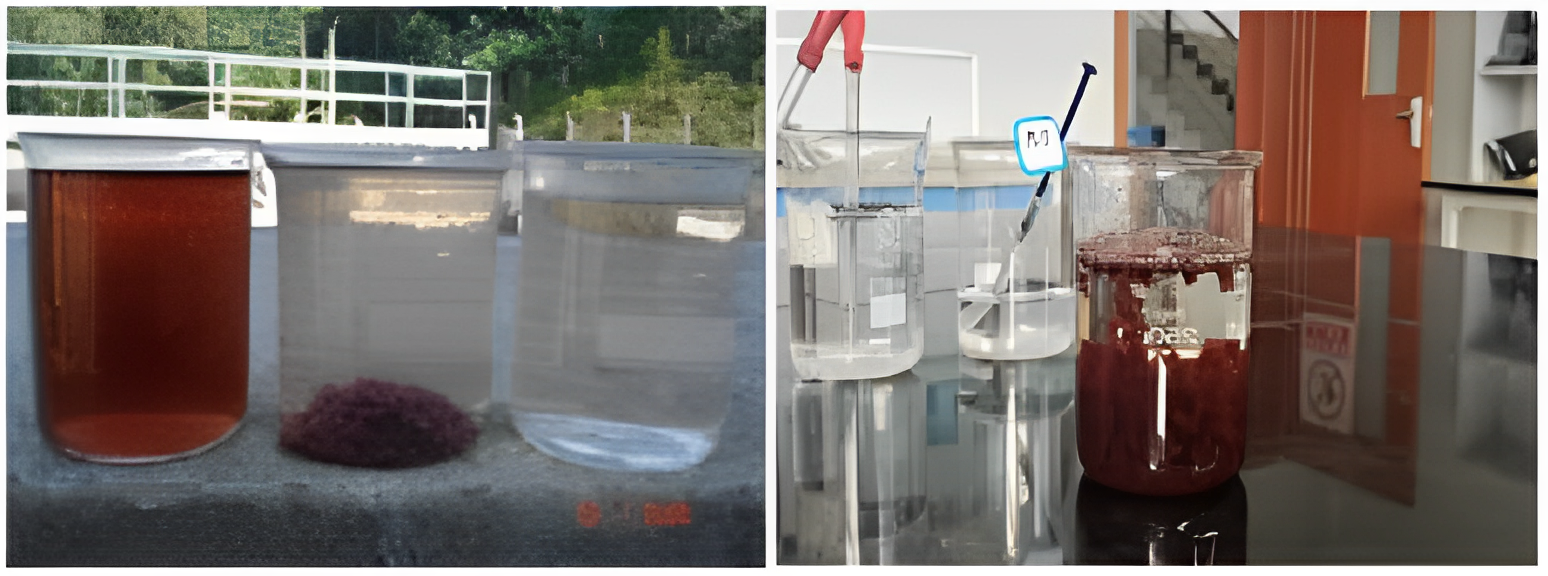

DEOILERS/DEIMULSIFIERS:

A specialty polymer for separation of oil in water emulsions. Our Deoiler chemicals are applied dependant on whether water is discharged directly overboard or whether the produced water is collected in slop tanks prior to discharge.

Deoiler is a process in which oil is removed from a material or surface. Demulsification is the breaking of a crude oil emulsion into oil and water phases. Deoiler enhances bulk oil/water separation for the purpose of facilitating downstream oil removal.

These Deoiler are uniform liquids free from visible impurities and are soluble in water in all proportions. They separate two liquids having different specific gravities.

Features:

| It is Water Soluble. | |

| Low DosagesRate. | |

| Excellent Water Quality. | |

| Does not contain harmful Volatile Solvents. | |

| It enhances Bulk Oil/Water Separation. |

COLOUR REMOVAL AIDS:

A specialty polymer for the removal of colouringmatter from effluents.Often treatment of the effluent streams requires removal of colouring material from the water prior to discharge. Coloured water is highly objectionable and impairs down-stream use.However, certain chemicals that colour water are in true solution and are more difficult to remove.

Our colour removal polymers are effectivein removing such colouring matters from effluents.With an objective to serve clients in the best possible manner, we are engrossed in providing top notch grade colour removal chemicals. These chemicals are widely used in textile, paper, and other related industries for removing the colour from items. The offered chemicals are processed under the observation of our ingenious professionals with the aid of sophisticated methodology.

Features:

| Mainly used for colour removal treatment for high-colority effluent from textile dyeing & printing mills, dyestuffs & pigment mills, ink & paper making mills. | |

| Suitable to treat waste water with Reactive dye, Acid dye, Disperse dye, Direct dye, Sulphur dye, Vat dye etc. | |

| Can be used in the production process of Paper &Pulp as retention agent. | |

| Stronger Decolorization (60%~99.9%) and removal of COD & BOD (50%~80%). | |

| Faster Sedimentation, Better Flocculation, Fewer Sludge. | |

| Non-Pollution(No Aluminium, Chlorine, Heavy Metal Ions etc.) |

CHLORINE DIOXIDE GENERATOR & CHEMICAL DOSING SYSTEMS

CHLORINE DIOXIDE (CLO2) – Bio-Clorox

Chlorine dioxide is an extremely reactive gas, and because of its instability, cannot be stored. It must only be produced in the required quantities in special generators on the site where it is used. Chlorine dioxide offers several advantages when compared with chlorine for water disinfection. Chlorine being the disinfectant mainly used. The disinfecting power of chlorine dioxide increases slightly with increasing pH, whereas with chlorine the disinfecting power reduces.

Chlorine dioxide remains stable in the pipeline system over a longer period and ensures microbiological protection of the water for many more hours, or even several days. Ammonia and ammonium, which cause significant chlorine depletion, are not attacked by chlorine dioxide, so chlorine dioxide is fully available forbactericidal action.

Chlorophenols, the compounds with intense odours, that are often produced during water chlorination, are not formed when chlorine dioxide is used. Trihalomethanes (THMs), a group of substances, which, like their best-known example, chloroform, (are suspected of being carcinogenic) are produced when chlorine reacts with natural water components (humic acids, fulvic acids, etc.). Measured THM concentrations, are drastically reduced, if present at all, when chlorine dioxide is used.

STABLE, SAFE, CLEAN

The disinfecting power of chlorine dioxide is always able to develop in full because it does not react with ammonia or ammonium. By contrast, the chlorination of water can produce chlorophenols and other strongly smelling compounds. This is not the case with chlorine dioxide. Trihalomethanes (THMs) and other chlorinated hydrocarbons are also not formed.

Advantages of Chlorine Dioxide (ClO2):

| Disinfection power is independent of pH. | |

| High residual effect thanks to long-term stability in the pipeline system. | |

| Reduction of the biofilm in pipelines and tanks, hence reliable protection of entire water systems against legionella contamination. | |

| No reaction with ammonia or ammonium. | |

| No formation of chorophenols and other intense odour compounds which can be produced in water chlorination. |

ALLIED SERVICES & SOLUTIONS SUPPORT

PEOPLE

Our innovative monitoring and control technology, comprehensive in-house analytical and laboratory services, safety practices, asset protection and stringent quality control ensure that your team excels at their daily operations and follow safety measures.

PLANET

At Bio-Teck, we optimize chemical usage and mitigate risks by helping our customers reduce the risk of water-borne pathogens in their facilities by implementing cost-effective, proactive processes and make them an inherent part of their current quality assurance programs.

PROFIT

The reduced costs of water, energy, and effluent ensure more profitability to your company, apart from our ‘Return on Investment’ projects, reduction in total cost of operation and improved operating and production efficiency and extended lifespan of your equipment.

| WATER & SYSTEM AUDIT/SURVEY… | |

| OPTIMUM PROGRAM SELECTION & PRODUCT RECOMMENDATIONS… | |

| APPLICATION & MONITORING SUPPORT… | |

| TROUBLE SHOOTING WITH OPERATOR TRAINING… | |

| TREATMENT REVIEW & AUDIT… | |

| WATER AND ENERGY AUDIT. | |

| SYSTEM SURVEY & AUDITS. | |

| ANNUAL MAINTENANCE CONTRACTS. | |

| SUPPLY OF WTP SPARES ETC. | |

| REGULAR TECHNICAL SUPPORT/SERVICES. | |

| WATER AND SCALE ANALYSIS. | |

| REGULAR AND PERIODIC TECHNICAL AUDITS AND REVIEW OF SYSTEMS AND SUGGEST PROGRAMS. | |

| OPERATORS TRAINING & SUPPORT. |

(1).jpeg)

.jpeg)